creep and fatigue test|creep testing machine diagram : distributing 1.1 This test method covers the determination of creep-fatigue crack growth properties of nominally homogeneous materials by use of pre-cracked compact type, C(T), .

Hotéis e resorts. Papagayo Beach Resort. Construída no topo da área de Jan Thiel, as espaçosas villas do Papagayo Beach Resort exibem um toque moderno com uma elegância tropical, inteligentemente concebidos para permitir uma integração perfeita entre a vida no interior e ao ar livre.

{plog:ftitle_list}

Gostaríamos de exibir a descriçãoaqui, mas o site que você .

It is primarily concerned with the testing of round bar test specimens subjected to uniaxial loading in either force or strain control. The focus of the procedure is on tests in which .

There are two general types of fatigue tests conducted. One test focuses on the nominal stress required to cause a fatigue failure in some number of cycles. This test results in data . Fatigue testing and creep testing serve different purposes in evaluating material behavior under specific loading conditions. While fatigue testing focuses on cyclic loading and crack propagation, creep testing .The creep–fatigue interaction behavior of materials is frequently simulated in the laboratory by high-temperature low-cycle fatigue (HTLCF) or creep-fatigue crack growth (CFCG) tests .The subsequent sections of this report examine, in detail, current design practice for basic creep- fatigue damage evaluation, creep-fatigue damage evaluation in the presence of detrimental .

1.1 This test method covers the determination of creep-fatigue crack growth properties of nominally homogeneous materials by use of pre-cracked compact type, C(T), .

Creep-fatigue tests may involve investigation of creep-fatigue as well as oxidation-fatigue interactions. Depending upon composition and crystallographic structure, alloys are more-or .What is the difference between creep test and fatigue test? Creep testing measures how a material deforms under constant load over time, while fatigue testing examines how it responds to repeated cyclic loading.

what does test impact mean

strain versus time creep curve

The methodology appears to be robust when the stress range is within the limits of the creep data. The creep-fatigue testing at high strain ranges results in peak stresses that . Creep, Fatigue and Creep–Fatigue Interaction are among the major life limiting factors affecting the deformation and damage behaviour of components used in several high temperature applications including nuclear, aerospace, petrochemical and offshore industries.A thorough understanding of the material behaviour under the above loading conditions is . Another observation from creep-fatigue interaction test results in Fig. 16 is that linear damage rule is conservative for all conditions, except for the loading block with R = 0.1 at 23 °C. The reason for longer lives in the presense of creep may be explained by crack formation and crack tip morphology in polyethylene .The present work takes a new look at the high temperature strength of single crystal (SX) Ni-base superalloys. It compares high temperature constant strain rate (CSR) testing, creep testing, and out-of-phase thermomechanical fatigue (OP TMF) testing, which represent key characterization methods supporting alloy development and component design in SX material science and .

Fatigue and creep refer to the failure mechanisms of materials under long-term stress. Fatigue occurs when a material experiences repeated loading cycles, leading to the formation of cracks that can eventually result in fracture, while creep is the gradual deformation of a material under constant stress over time, often occurring at high temperatures. Understanding these .Creep-fatigue is the initiation and subsequent growth of flaws under cyclic load interspersed with hold periods at constant, or slowly varying, load. . controlled fatigue test with holds will fail in fewer cycles than an equivalent pure fatigue test with the same strain range and at the same temperature but without any hold periods. Similarly .

Type 4 tests are generally known as thermo-mechanical fatigue tests. The strain-controlled fatigue test (type 1) is the most common one. Hold-Time Effects in Strain-Controlled Fatigue. The principal method of studying creep-fatigue interactions has been to conduct strain-controlled fatigue tests with variable frequencies with and without a .Creep Test The creep test, also known as the stress relaxation test, is a destructive way of evaluating a material’s durability and thermal stability. A creep test is one in which the specimen is heated for an extended period and supplied with a constant tensile force or tensile stress. . The Standard Test Method for Creep and Fatigue, ASTM .

1.3 Two types of creep behavior are generally observed in materials during creep-fatigue crack growth tests: creep-ductile and creep-brittle (1) 2.For highly creep-ductile materials that have rupture ductility of 10 % or higher, creep strains dominate and creep-fatigue crack growth is accompanied by substantial time-dependent creep strains near the crack tip.The creep test, in some instances referred to as stress relaxation test, is a destructive materials testing method for determination of the long-term strength and heat resistance of a material.When running a creep test, the specimen is subjected to increased temperature conditions for an extended period of time and loaded with a constant tensile force or tensile .

However, when creep-fatigue tests are carried out with a hold time at maximum tensile strain, there is a continuous decrease of number of cycles to fracture with the tensile hold time in vacuum as in air. In this alloy system creep-fatigue interactions are the dominating damage mechanism. While continuous fatigue gives rise to a transgranular .The development of creep testing methods and the formulation of creep laws, such as the Norton-Bailey law, have been instrumental in predicting creep behavior in materials. . on fatigue analysis to ensure the durability of components such as engine parts, suspension systems, and chassis. Fatigue testing and analysis help in predicting the .be good measures for the predictability of creep-fatigue models when creep dominates. The creep fatigue tests with the relatively short hold times in stress control do produce extensively larger creep strains than corresponding relaxation tests but .

High total strain-controlled creep-fatigue tests of 1.8% were performed for a directionally-solidified Ni-based superalloy, DZ445, at 900 °C in air. Dwell times of 0, 2, and 5 min. were .creep rate as a function of temperature and applied stress. The constant A, the exponent n, and the activation energy for creep Qc are material characteristics and can be determined from a series of creep tests. Several tests have to be carried out . Only a very few studies precisely tackle the microstructural variations occurring during creep-fatigue tests [14,22,27,28] and their influence on the mechanical behaviour of 9% Cr steels.Failure, Fatigue and Creep 27.1 Failure A material, component or structure is deemed to have failed when its ability to fully satisfy the original design function ceases. This may be due to a variety of causes. . Much fatigue testing is carried out using alternating stress cycles in which am is zero but, in

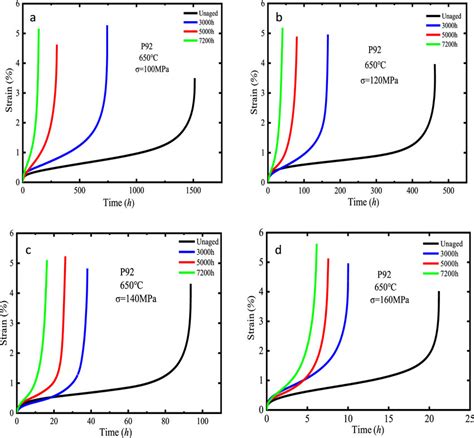

It is easy to identify fatigue failure, as it leaves a distinct pattern of smooth slow crack growth around the epicentre, and rough brittle fracture marks everywhere else. Fatigue Testing. In a fatigue test, a sinusoidal stress is . Creep-fatigue testing of alloy 617 was performed in air, vacuum, and purified Ar environments at 1000 °C. Tests were performed in axial strain control at total strain ranges of 0.3% and 1.0% . This work focused on the interaction of creep and fatigue and cyclic strain analysis in high-chromium ferritic P92 steel based on load-controlled creep-fatigue (CF) tests and conventional creep test at 873 K. Mechanical testing shows that the cyclic load inhibits the propagation of creep damage in the P92 steel and CF interaction becomes more severe with .

Data that may be determined from creep-fatigue tests performed under conditions in which creep-fatigue deformation and damage is generated simultaneously include (a) cyclic stress- strain deformation response (b) cyclic creep (or relaxation) deformation response (c) cyclic hardening, cyclic softening response (d) cycles to formation of a single .Introduction. ASTM E2714 is a standardized test method that outlines procedures for conducting creep-fatigue testing of metallic materials. It evaluates the behavior of materials under conditions where cyclic loading and sustained loading (creep) co-occur, which is common in high-temperature environments such as those found in power plants, jet engines, and other critical . The Standard E2760 restricts creep–fatigue crack growth tests to only one specimen geometry and only under conditions of load-control. The amount of crack extension in the specimens that is considered valid is limited by ratcheting in the specimens with cycles. Additional specimen geometries and displacement-controlled tests should be .

Creep-fatigue interaction behavior of ferritic steels and austenitic stainless-steels — covers properties, test methods and the latest models for applying the test data to components. Creep-fatigue interactions in nickel-base superalloys being considered for use or already in use in advanced nuclear plants and in gas turbines — discusses . In engineering damage mechanics, creep damage induced by intergranular defects such as voids depends on creep time, while fatigue damage derived from surface flaws relates to cycle number [7], [8].The corresponding damage models were also developed in recent decades, such as frequency modified life (FML) model [9] describing the fatigue damage, and time . Complex service-like relaxation- and creep-fatigue tests with strain- and stress-controlled dwells and fatigue cycle durations of approx. 2200 s were performed exemplarily on a grade P92 steel at 620 °C in this study. The results indicate deviations in the prevailing creep mechanisms of long-term relaxation and creep dwells, affecting . After creep-fatigue tests for the specimen N4 (Δε t =0.5%, t h =3600 s, Table 1), the intergranular crack appears on the specimen surface, accompanied with the abscission of oxidation film and δ phase, as displayed in Fig. 11 e. More detailed TEM investigations of cavity growth under creep-fatigue loading are shown in Fig. 11 f–h.

what does test impact mean in assessment

The fatigue crack initiation resistance of an alloy is determined by conducting a series of tests over a range of values of stress amplitude or strain range. The observed number of cycles to failure is plotted against the stress amplitude or strain range to obtain a fatigue curve. The fatigue properties quoted for an alloy are typically the constants used in the equation(s) .

difference between fatigue and creep

what does the impact test consist of

creep testing machine diagram

webMicro Macro Mundo Inc. Founded in 1986 in Miami Florida U.S.A. presents: The World best collection of products for your Hobby in Model Trains, Static plastic & wooden models .

creep and fatigue test|creep testing machine diagram